What is PUR hot melt adhesive ?

As a leading manufacturer and supplier of advanced bonding solutions, Adhesive (Shanghai) Co., Ltd specializes in high-performance hot melt adhesives, including cutting-edge PUR (Polyurethane Reactive) hot melt adhesive. This article addresses common questions about hot melt adhesives, with a focus on PUR technology, its applications, and the unique advantages it offers.

1. What is PUR Hot Melt Adhesive?

PUR hot melt adhesive is a specialized type of thermoplastic adhesive that combines the rapid bonding properties of traditional hot melt adhesives with the enhanced durability of reactive chemistry. Unlike standard hot melts, PUR hot melt adhesive undergo a secondary curing process when exposed to moisture in the air. This reaction forms irreversible cross-linked polymers, resulting in bonds that are exceptionally strong, flexible, and resistant to heat, chemicals, and environmental stress.

Key Features of PUR Hot Melt Adhesive:

- Thermoplastic base: Applied in molten form (typically at 110–130°C).

- Reactive curing: Reacts with ambient moisture to form permanent bonds.

- Versatility: Bonds diverse substrates, including plastics, metals, wood, and textiles.

- High performance: Suitable for demanding industries like automotive, electronics, and construction.

At Adhesive (Shanghai) Co., Ltd, our PUR formulations are engineered for precision, ensuring optimal adhesion across industries. Our R&D team tailors products to meet specific client needs, from low-temperature applications to high-strength industrial uses.

2. What is Hot Melt Glue Best Used For?

Hot melt adhesives (HMAs) are widely used for their fast-setting properties and ease of application. Common applications include:

- Packaging: Carton sealing, box assembly, and label attachment.

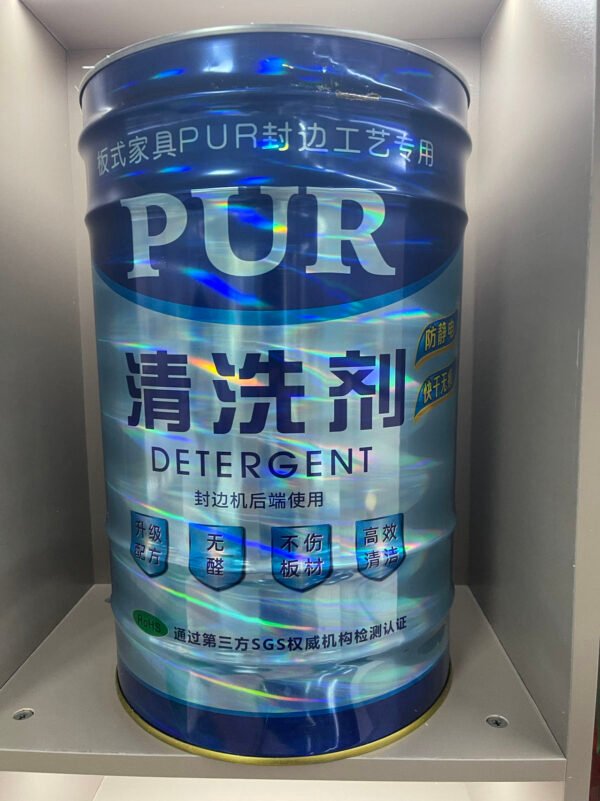

- Woodworking: Edge banding, veneering, and furniture assembly.

- Textiles: Seam bonding in apparel and footwear.

- Automotive: Interior trim assembly and wire harnessing.

- Electronics: Component fixation and wire insulation.

Adhesive (Shanghai) Co., Ltd provides HMAs with tailored viscosity, open time, and temperature resistance. For example, our FastBond 300 Series is optimized for high-speed packaging lines, reducing downtime by 20% compared to industry standards.

3. What Does PUR Stand for in Glue?

PUR stands for Polyurethane Reactive, referring to adhesives that contain urethane prepolymers with isocyanate groups. These groups react with moisture to form urea linkages, creating a robust polymer network. This curing mechanism distinguishes PUR from non-reactive hot melts, which solidify solely through cooling.

4. Is Hot Melt Glue Permanent?

Traditional hot melt adhesives (e.g., EVA-based) are thermoplastic, meaning they soften under heat and can be re-melted. While they provide strong initial bonds, they are not ideal for high-temperature environments.

PUR hot melts, however, become thermoset after curing. The cross-linked structure makes the bond irreversible, offering permanent adhesion even under extreme conditions. For instance, our PUR-Shield 850 withstands temperatures up to 150°C, making it a preferred choice for automotive under-the-hood applications.

5. How Long Does PUR Glue Last?

The shelf life of uncured PUR hot melt adhesive is typically 6–12 months when stored in moisture-proof containers at <30°C. Once applied, the curing process begins immediately, with full strength achieved in 24–72 hours, depending on humidity levels.

Post-curing, PUR bonds retain their integrity for years, even in harsh environments. For example, our PUR-Flex 600 has been tested to maintain 90% of its strength after 5 years in outdoor settings.

6. Is Hot Melt Just Hot Glue?

While “hot melt” and “hot glue” are often used interchangeably, there are distinctions:

- Consumer-grade hot glue (e.g., craft sticks) refers to low-temperature EVA adhesives.

- Industrial hot melt adhesives (including PUR hot melt adhesive) are engineered for specific performance criteria, such as high shear strength or chemical resistance.

Adhesive (Shanghai) Co., Ltd focuses on industrial-grade solutions, ensuring reliability for critical applications like medical device assembly or aerospace composites.

7. What is an Alternative to Hot Melt Adhesive?

Alternatives include:

- Solvent-based adhesives: Offer strong bonds but pose environmental and health risks.

- Water-based adhesives: Eco-friendly but require longer drying times.

- Epoxies/cyanoacrylates: High strength but lack flexibility.

PUR hot melts strike a balance, combining speed, strength, and sustainability. For clients seeking solvent-free options, our EcoBond PUR Series reduces VOC emissions by 95% compared to traditional adhesives.

8. How Strong is Hot Melt Glue?

Standard HMAs have shear strengths of 3–10 MPa, suitable for lightweight applications. PUR hot melts, however, achieve 15–25 MPa, rivaling structural epoxies. Our PUR-Force 900 adhesive, for instance, bonds aluminum with a lap shear strength of 22 MPa, ideal for HVAC system manufacturing.

9. How Long Does PUR Glue Cure?

PUR adhesives achieve handling strength in 5–30 minutes, depending on substrate porosity and humidity. Full curing takes 24–72 hours. At Adhesive (Shanghai) Co., Ltd, we offer RapidCure PUR formulations that reduce handling time to 3 minutes, enhancing production efficiency for clients like Samsung and Bosch.

10. What Are the Disadvantages of Hot Melt Glue?

- Temperature sensitivity: Standard HMAs soften above 60°C.

- Limited gap-filling: Poor performance on uneven surfaces.

- Moisture sensitivity (PUR): Requires dry storage.

Our innovations address these issues. For example, PUR-TempShield retains strength up to 180°C, while PUR-Fill Pro accommodates gaps up to 2 mm.

11. What is PUR Used For?

PUR adhesives excel in:

- Automotive: Windshield bonding, headlight assembly.

- Electronics: Smartphone screen lamination, circuit board potting.

- Construction: Insulated glass window sealing.

- Footwear: Midsole bonding for Nike, Adidas.

Adhesive (Shanghai) Co., Ltd has supplied PUR adhesives for over 500 automotive assembly lines globally, including Tesla’s Shanghai Gigafactory.

12. How Does Hot Melt Adhesive Work?

HMAs are applied in molten form (120–180°C). Upon cooling, they solidify, creating mechanical bonds. PUR adhesives add a chemical reaction: isocyanate groups react with moisture, forming covalent bonds with substrates. This dual mechanism ensures both immediate grab and long-term durability.

Why Choose Adhesive (Shanghai) Co., Ltd?

- 25+ years of expertise: ISO 9001-certified manufacturing.

- Custom solutions: Tailored adhesives for niche industries.

- Global reach: Serving 50+ countries with warehouses in the EU and USA.

- Sustainability: 100% recyclable packaging and low-carbon formulations.

For a quote or technical consultation, contact us at emily.gu@great-adhesive.com or visit great-adhesive.com

Leave a Reply