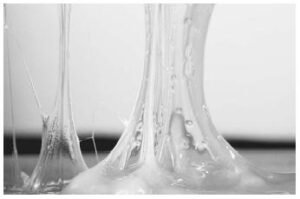

PUR adhesive

PUR Adhesive (Polyurethane Reactive Adhesive) is a cutting-edge, moisture-curing polymer renowned for its unparalleled strength, durability, and versatility. Designed to bond diverse substrates—including wood, plastics, metals, glass, and composites—PUR adhesive leverages a unique chemical reaction with ambient moisture to form robust, flexible bonds resistant to extreme temperatures (-40°C to +120°C), water, chemicals, and mechanical stress.

Key Features:

-

100% Solid, Solvent-Free Formula: Ensures eco-friendly application with zero volatile organic compounds (VOCs).

-

Dual-Stage Curing: Rapid initial set (5–30 seconds) for immediate handling strength, followed by full cross-linking within 24–72 hours for maximum structural integrity.

-

Material Versatility: Bonds dissimilar substrates (e.g., wood-to-metal, plastic-to-glass) with exceptional adhesion strength (up to 15 MPa).

-

Environmental Resistance: Ideal for outdoor, marine, and high-stress industrial environments du

-

e to waterproof, UV-stable, and thermal-resistant properties.

Product Specifications

1. Technical Parameters

| Property | Details |

|---|---|

| Viscosity | 3,000–16,000 cP (adjustable for spray, extrusion, or roll coating)7. |

| Open Time | 1–10 minutes (customizable for automated or manual processes)7. |

| Cure Time | Initial handling: 15–150 seconds; Full cure: 24–72 hours13. |

| Hardness (Shore D) | 35–65 (flexible to rigid bonds based on application needs)7. |

| Color Options | Off-white, gray, black (UV-tracer dye available for quality inspection)7. |

| Packaging | 0.1-gallon cartridges, 5-gallon pails, 55-gallon drums7. |

2. Compliance & Safety

-

Certifications: ISO 9001, ISO 14001, REACH, RoHS compliant.

-

Non-Toxic Post-Cure: Safe for indirect food contact and indoor use after full polymerization.

Applications Across Industries

PUR adhesive’s adaptability makes it indispensable in sectors demanding precision and reliability:

-

Woodworking & Furniture

-

Lamination: Seamless bonding of veneers, MDF, and solid wood for cabinets, flooring, and decorative panels.

-

Edge Banding: High-speed production with minimal waste and superior edge retention.

-

-

Automotive & Aerospace

-

Structural Assembly: Lightweight bonding of dashboards, door panels, and composite materials to enhance crash resistance.

-

-

Electronics

-

Component Encapsulation: Moisture-proof sealing for circuit boards and displays.

-

-

Construction

-

Insulation & Roofing: Weatherproof adhesion for panels, foams, and waterproof membranes.

-

-

Packaging

-

Airtight Seals: Tamper-resistant bonding for food, pharmaceutical, and luxury packaging.

-

Why Choose Great-Adhesive’s PUR Adhesive?

1. Vertical Integration for Cost Efficiency

As a self-sufficient manufacturer with in-house raw material production, Great-Adhesive eliminates middlemen, reducing costs by 20–30% compared to competitors. Our proprietary polyol and isocyanate synthesis ensures consistent quality and scalable supply.

2. Tailored Formulations

Customize viscosity, cure time, and hardness to match your production line’s speed, temperature, and substrate requirements.

3. Sustainable Manufacturing

-

Zero Waste: Precision dispensing systems minimize adhesive waste.

-

Energy-Efficient Production: Solar-powered facilities and closed-loop recycling reduce carbon footprint.

4. Global Compliance & Support

-

24/7 Technical Assistance: On-site troubleshooting and R&D collaboration.

-

Fast Logistics: Warehouses in North America, Europe, and Asia ensure timely delivery.

Production Process: Precision Meets Innovation

Great-Adhesive’s state-of-the-art manufacturing integrates automation and rigorous QC:

-

Raw Material Synthesis

-

Proprietary polyols and isocyanates are synthesized under controlled conditions to ensure purity and reactivity.

-

-

Pre-Polymerization

-

Di-isocyanates react with polyols to form stable prepolymers, optimized for shelf life (12+ months) and moisture sensitivity.

-

-

Compounding & Testing

-

Additives (UV stabilizers, flexibilizers) are blended. Each batch undergoes tensile, peel, and humidity resistance tests.

-

-

Packaging

-

Nitrogen-flushed, moisture-proof packaging preserves adhesive integrity during storage and transit.

-

Contact Us for Custom Solutions

📞 WhatsApp: +86-15618525178

📧 Email: emily.gu@great-adhesive.com

Reviews

There are no reviews yet.