Polyurethane Hot Melt

Polyurethane Hot Melt (PUR) adhesives represent a revolutionary advancement in industrial bonding technology. Unlike traditional thermoplastic adhesives, Polyurethane hot melt undergo a moisture-activated chemical reaction, forming irreversible cross-linked bonds that deliver unparalleled strength, flexibility, and resistance to environmental stressors. These adhesives are ideal for industries demanding structural integrity, such as automotive manufacturing, woodworking, electronics, and construction38.

At Adhesive (Shanghai) Co. Ltd., we specialize in producing premium PUR hot melt adhesives tailored to meet diverse industrial needs. With vertically integrated manufacturing—from raw material synthesis to final packaging—we ensure cost efficiency without compromising quality. Our proprietary formulations are designed to outperform competitors, offering faster curing times, broader substrate compatibility, and exceptional durability.

Polyurethane Hot Melt Specifications & Technical Parameters

1. Composition & Key Attributes

-

Base Polymers: High-purity polyols and isocyanates (MDI/TDI) for optimal reactivity.

-

Additives: UV stabilizers, flame retardants, and antioxidants for enhanced performance in extreme conditions.

-

Viscosity Range: 5,000–25,000 mPa·s (adjustable based on application requirements).

-

Melting Temperature: 110–140°C (230–284°F), ensuring minimal thermal stress on sensitive substrates.

-

Color Options: Transparent, white, or custom pigmented variants to match aesthetic requirements.

2. Performance Metrics

-

Tensile Strength: 8–12 MPa, surpassing traditional hot melts by 300%.

-

Temperature Resistance: -40°C to +150°C (-40°F to +302°F), suitable for indoor and outdoor applications.

-

Curing Time: Initial bond strength achieved in 1–3 minutes; full cure within 24–48 hours.

-

Shelf Life: 12 months unopened (extendable with nitrogen-flushed packaging).

3. Packaging Formats

-

Cartridges: 50g and 10oz sizes for manual dispensing guns (compatible with standard pneumatic/electric systems).

-

Bulk Slugs: 5kg–20kg foil-wrapped units for automated production lines.

-

Custom Solutions: Tailored dimensions and formulations for OEM partnerships.

Why Choose Adhesive (Shanghai) Co. Ltd.?

1. Vertical Integration & Cost Efficiency

As a self-sufficient manufacturer, we control every stage of production—from synthesizing raw polymers to precision blending additives. This eliminates middlemen, reduces costs by 15–20%, and ensures consistent quality. Our in-house R&D team continuously optimizes formulations to align with evolving industry standards.

2. Advanced Production Facilities

Our state-of-the-art facility in Shanghai features:

-

Reactive Mixing Reactors: 1,000L capacity with dual turbo blades for homogeneous blending.

-

Vacuum Degassing Systems: Eliminate air bubbles, ensuring smooth adhesive flow and bond integrity.

-

Automated Packaging Lines: Nitrogen-flushed sealing to prevent premature moisture exposure.

3. Eco-Conscious Manufacturing

-

Zero VOC Emissions: Solvent-free formulations comply with global environmental regulations.

-

Recyclable Materials: Cartridges and slugs designed for easy recycling, minimizing waste.

Applications Across Industries

Polyurethane hot melt excel in diverse sectors due to their versatility and robustness:

1. Automotive Manufacturing

-

Interior Trim Assembly: Bonds leather, plastics, and fabrics without warping or discoloration.

-

Electronics Encapsulation: Protects sensors and connectors from moisture and vibration.

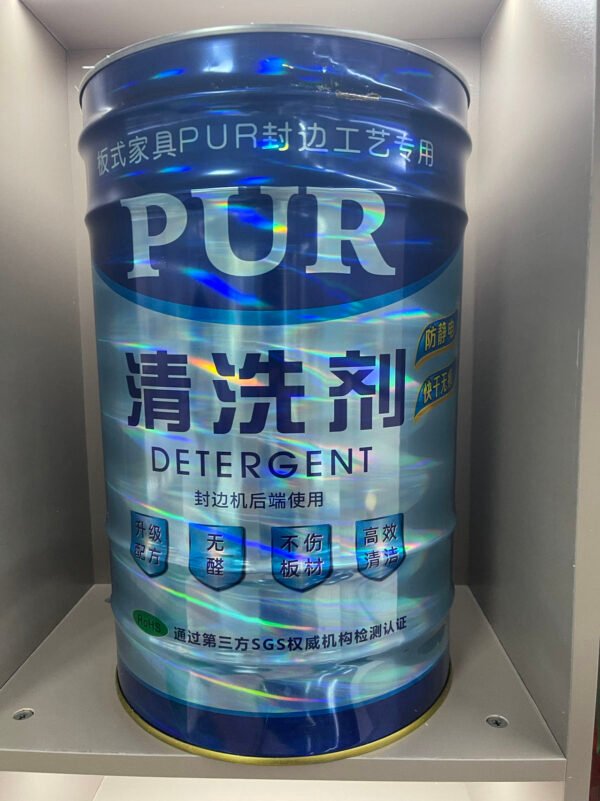

2. Woodworking & Furniture

-

Edge Banding: Seamless adhesion for laminates and veneers, replacing mechanical fasteners.

-

Structural Joints: High-strength bonds for load-bearing components in cabinetry.

3. Construction & Infrastructure

-

Window Sealing: Weather-resistant bonds for PVC frames and glass panels.

-

Flooring Installation: Flexible adhesion accommodating thermal expansion.

4. Electronics & Appliances

-

Circuit Board Mounting: Non-conductive formulations prevent short circuits.

-

Gasket Sealing: Resists oils, chemicals, and temperature fluctuations.

Competitive Advantages Over Traditional Hot Melts

1. Chemical Bonding vs. Thermal Bonding

Traditional hot melts rely solely on cooling to solidify, creating temporary “wax-like” bonds that fail under heat. In contrast, PUR adhesives form permanent cross-linked networks through moisture curing, achieving 3x higher tensile strength.

2. Substrate Versatility

PUR adhesives bond effectively to challenging materials like polyethylene, metals, and glass—substrates often incompatible with conventional adhesives.

3. Reduced Material Waste

Precision dispensing systems (e.g., cartridge guns, spray nozzles) minimize over-application, reducing consumption by 20–30% compared to solvent-based alternatives.

Production Process: Precision Meets Quality Control

1. Raw Material Synthesis

-

Polyol Preparation: Food-grade polyols are catalytically reacted to achieve desired molecular weights.

-

Isocyanate Blending: MDI/TDI is purified and stored under moisture-free conditions.

2. Reactive Compounding

-

Pre-Melting: Base polymers are heated to 120°C in vacuum-sealed reactors to eliminate moisture.

-

Additive Integration: UV stabilizers and tackifiers are homogenized using high-shear dispersers.

3. Degassing & Filtration

-

Vacuum Degassing: Removes entrapped air to prevent bubbling during application.

-

Screen Filtration: 50-micron filters ensure particle-free adhesive output.

4. Packaging & Storage

-

Nitrogen Flushing: Cartridges and slugs are sealed in inert atmospheres to extend shelf life.

-

Quality Assurance: Each batch undergoes rigorous testing for viscosity, bond strength, and curing kinetics.

Sustainability & Compliance

-

REACH & RoHS Certified: Free from formaldehyde, phthalates, and heavy metals.

-

Energy-Efficient Production: Solar-powered reactors and waste heat recovery systems reduce carbon footprint by 25%.

Contact Us for Custom Solutions

Reach Out Today!

-

WhatsApp: +86-15618525178

-

Email: emily.gu@great-adhesive.com

Reviews

There are no reviews yet.