PSA hot melt adhesive

PSA hot melt adhesive has emerged as a standout solution for numerous applications. This article aims to provide an in – depth exploration of this remarkable product, delving into its various aspects from product parameters to company background, all geared towards highlighting its exceptional advantages and encouraging potential customers to reach out to Adhesive (Shanghai) Co., Ltd.

Product Description

PSA hot melt adhesive, or pressure – sensitive adhesive hot melt adhesive, represents a cutting – edge adhesive technology. It is a type of adhesive that exhibits tacky properties at ambient temperatures and can form a bond when pressure is applied. What sets it apart is its unique formulation and characteristics that make it suitable for a wide array of industries.

This adhesive is composed of several key components. The base polymer plays a crucial role in determining its fundamental properties such as viscosity and elasticity. Common base polymers include ethylene – vinyl acetate (EVA), polyolefin, and polyamide. These polymers provide the adhesive with its inherent tackiness and strength.

Alongside the base polymer, tackifiers are incorporated to enhance the adhesive’s tackiness. They improve the adhesive’s ability to wet the substrate and form a strong bond upon contact. Additionally, plasticizers may be added to modify the flexibility and workability of the adhesive. They help in achieving the desired consistency and application characteristics.

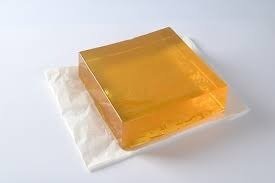

The appearance of PSA hot melt adhesive can vary depending on its specific formulation and intended use. Generally, it comes in the form of granules or pellets, making it easy to handle and apply in various production processes. The color can range from transparent to slightly yellowish, allowing it to blend in with different substrates and applications.

Product Parameters

The product parameters of PSA hot melt adhesive are meticulously designed to meet diverse application requirements. Here are some key parameters:

-

Viscosity: Measured in centipoise (cps), the viscosity of the adhesive determines its flowability. For instance, a lower viscosity adhesive (in the range of 1000 – 3000 cps) is suitable for fine – line applications and porous substrates, as it can easily penetrate and fill in the pores. A higher viscosity adhesive (above 5000 cps) is more appropriate for applications requiring a thicker adhesive layer or on non – porous surfaces.

-

Open Time: This refers to the time during which the adhesive remains tacky after application and before it starts to solidify. The open time of PSA hot melt adhesive typically ranges from a few seconds to several minutes. It is influenced by factors such as temperature, adhesive thickness, and substrate type. A longer open time allows for more precise positioning of materials, which is beneficial in applications like label application where accurate alignment is crucial.

-

Set Time: The set time indicates how quickly the adhesive achieves sufficient strength to hold the bonded materials together. It can vary from instantaneous setting to several minutes. A shorter set time is advantageous in high – speed production lines where quick assembly is required, such as in the packaging industry for sealing products.

-

Peel Strength: Measured in units like N/25mm, peel strength reflects the adhesive’s ability to resist separation when a force is applied perpendicular to the bond line. PSA hot melt adhesives can offer peel strengths ranging from low values suitable for removable applications, like repositionable labels, to high values exceeding 100 N/25mm for permanent bonds in applications such as automotive trim attachment.

-

Temperature Resistance: Depending on the specific formulation, PSA hot melt adhesives can withstand a range of temperatures. Some are designed for low – temperature applications, maintaining their bond integrity even at temperatures as low as – 20°C, while others can endure high temperatures up to 200°C or more. This versatility makes them suitable for products that may be exposed to varying thermal conditions during usage or storage.

Company Introduction

Adhesive (Shanghai) Co., Ltd stands out in the adhesive industry due to its unique advantage of in – house raw material production. By controlling the raw material supply chain from the source, the company is able to significantly reduce production costs and maintain consistent quality.

The company boasts state – of – the – art production facilities and a team of highly skilled professionals dedicated to research and development, production, and quality control. With years of experience in the adhesive field, they have gained a deep understanding of market demands and application scenarios, enabling them to continuously innovate and improve their PSA hot melt adhesive products.

Adhesive (Shanghai) Co., Ltd is committed to providing high – quality adhesive solutions to customers worldwide. Their products are extensively used in industries such as packaging, automotive, electronics, construction, and textiles, earning a reputation for reliability and effectiveness.

Product Advantages and Selling Points

One of the primary advantages of PSA hot melt adhesive from Adhesive (Shanghai) Co., Ltd is its cost – effectiveness. Thanks to the company’s in – house raw material production, they can offer competitive prices without compromising on quality. This makes their products an attractive option for businesses looking to optimize their production costs without sacrificing adhesive performance.

In terms of performance, these adhesives exhibit exceptional bonding strength. They can adhere to a wide variety of substrates, including metals, plastics, paper, and textiles. Whether it’s bonding rigid materials like automotive parts or flexible materials such as packaging films, PSA hot melt adhesives deliver reliable and durable bonds. The high peel strength ensures that materials stay securely attached even under tension or stress.

Another significant advantage is their ease of application. PSA hot melt adhesives can be applied using various methods such as roll coating, spray application, and slot die coating, depending on the specific production process and substrate requirements. The adhesives melt and flow smoothly when heated, ensuring uniform application and minimal waste. The short set time allows for quick production cycles, enhancing overall productivity.

Moreover, these adhesives are environmentally friendly. They are free from harmful solvents and volatile organic compounds (VOCs) that can negatively impact air quality and human health. This makes them a safer choice for both workers and the environment, aligning with the growing emphasis on sustainability in industries worldwide.

Production Process

The production process of PSA hot melt adhesive at Adhesive (Shanghai) Co., Ltd is a well – orchestrated procedure that ensures the highest quality standards. It begins with the careful selection and preparation of raw materials. The in – house produced raw materials are thoroughly tested for consistency and purity to guarantee the desired adhesive properties.

Once the raw materials are ready, they are fed into specialized mixing equipment. Under precise temperature and mixing conditions, the components are blended together to form a homogeneous adhesive mixture. The mixing process is closely monitored to ensure the proper distribution of each ingredient and to achieve the desired viscosity and rheological properties.

After mixing, the adhesive undergoes a melting and homogenization stage. The mixture is heated to the appropriate temperature to ensure complete melting and uniformity. Any impurities or air bubbles are removed during this process to enhance the adhesive’s performance and appearance.

The molten adhesive is then extruded into the desired shape and size, such as granules or pellets. The extrusion process is controlled to ensure consistent dimensions and quality of the final product. The extruded adhesive is cooled and packaged in protective containers to maintain its stability and prevent contamination during storage and transportation.

Throughout the entire production process, strict quality control measures are implemented at each stage. Samples are regularly tested for parameters such as viscosity, peel strength, open time, and temperature resistance to ensure that the final product meets the specified quality standards and is ready for various applications.

Application Fields

The versatility of PSA hot melt adhesive makes it applicable in numerous industries. In the packaging industry, it is widely used for sealing boxes, envelopes, and labels. Its strong adhesion and quick setting properties make it ideal for high – speed packaging lines, ensuring products are securely packaged and ready for distribution.

In the automotive sector, PSA hot melt adhesives play a crucial role in attaching interior trim components, such as dashboards, door panels, and seats. They provide a reliable bond that can withstand the vibrations and temperature fluctuations commonly encountered in vehicles.

For the electronics industry, these adhesives are employed in the assembly of components like keyboards, speakers, and displays. Their ability to bond delicate electronic materials without causing damage and their resistance to electrical interference make them a preferred choice.

In the construction field, PSA hot melt adhesives are used for applications such as tiling, insulation, and weather – stripping installation. They offer excellent adhesion to building materials and can accommodate the dimensional changes that occur due to temperature and humidity variations.

The textile industry also benefits from PSA hot melt adhesives, which are utilized in garment assembly, fabric bonding, and decorative applications. They provide flexible bonds that allow textiles to maintain their comfort and functionality while enhancing the aesthetic appeal of the final products.

Customer Support and Service

Adhesive (Shanghai) Co., Ltd places great emphasis on customer satisfaction. They offer comprehensive customer support and service to ensure that clients receive the maximum benefit from their PSA hot melt adhesive products.

The company’s technical team is available to provide application guidance and troubleshooting assistance. Whether it’s advice on selecting the appropriate adhesive for a specific application, optimizing application parameters, or resolving any issues encountered during use, customers can rely on their expertise.

In addition, Adhesive (Shanghai) Co., Ltd offers customized solutions to meet the unique needs of different clients. They can tailor the formulation and properties of PSA hot melt adhesives to suit specific requirements, ensuring that the products perfectly match the client’s production process and application scenario.

For more information about PSA hot melt adhesive products, or to discuss your specific adhesive needs, please feel free to contact Adhesive (Shanghai) Co., Ltd. You can reach them via WhatsApp at +86 – 15618525178 or send an email to emily.gu@great – adhesive.com. Their dedicated team will be more than happy to assist you and provide the adhesive solutions that will enhance your production efficiency and product quality.

In conclusion, PSA hot melt adhesive from Adhesive (Shanghai) Co., Ltd is a superior adhesive product with a multitude of advantages. Its unique combination of cost – effectiveness, strong bonding performance, ease of application, and environmental – friendliness make it an excellent choice for a wide range of applications across various industries. By leveraging their in – house raw material production and commitment to quality, the company continues to deliver reliable and innovative adhesive solutions to customers worldwide. Don’t hesitate to reach out and explore how their PSA hot melt adhesives can benefit your business!

Reviews

There are no reviews yet.