Pressure sensitive adhesives

Adhesive (shanghai) Co., Ltd., headquartered in Shanghai, China, is a leading manufacturer of pressure-sensitive adhesives (PSA) with over two decades of expertise in polymer science and adhesive innovation. As a vertically integrated enterprise, we control every stage of production—from raw material synthesis to final product delivery—ensuring unmatched quality consistency, cost efficiency, and supply chain reliability. Our state-of-the-art facilities house advanced R&D labs and automated production lines, enabling us to deliver tailored adhesive solutions for industries ranging from automotive and electronics to medical devices and sustainable packaging.

Core Strengths:

- Raw Material Self-Sufficiency: Our proprietary synthesis of polymers, tackifiers, and additives eliminates reliance on third-party suppliers, reducing costs by 15–20% compared to industry averages.

- Global Compliance: Products meet ISO 9001, REACH, and FDA standards, ensuring safety for food-contact and medical applications.

- Customization Capabilities: From UV-curable PSAs to high-temperature-resistant formulations, our engineers collaborate closely with clients to solve unique bonding challenges.

Contact us today to discuss your project requirements:

WhatsApp: +86-15618525178 | Email: emily.gu@great-adhesive.com

Pressure sensitive adhesives Portfolio

Our PSA solutions are engineered for versatility, durability, and eco-efficiency. Below is an overview of our flagship products:

1. Rubber-Based PSAs

Color: Amber to translucent

Key Parameters:

- Tack Strength: 25–35 N/25mm

- Peel Resistance: 8–12 N/cm

- Temperature Range: -40°C to 80°C

Applications: General-purpose labels, automotive trim tapes, and industrial sealing.

Advantages: - Exceptional initial tack for rapid bonding.

- Cost-effective for high-volume production.

2. Acrylic PSAs

Color: Crystal clear to milky white

Key Parameters:

- UV Resistance: >1,000 hours (ASTM G154)

- Shear Strength: >50 hours @ 70°C

- Temperature Range: -30°C to 150°C

Applications: Outdoor signage, electronic displays, and medical device assembly.

Advantages: - Superior clarity and resistance to oxidation.

- Ideal for substrates like polycarbonate and glass.

3. Silicone PSAs

Color: Transparent

Key Parameters:

- Temperature Range: -60°C to 260°C

- Chemical Resistance: Resists oils, solvents, and acids.

Applications: Aerospace components, high-temperature gaskets, and flexible electronics.

Advantages: - Maintains pressure sensitive adhesives under extreme thermal cycling.

- Biocompatible for medical implants.

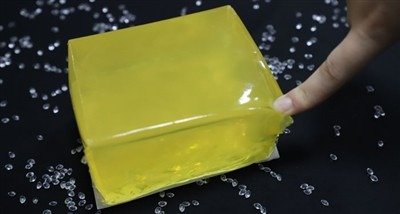

4. Hot-Melt PSAs (HMPSA)

Color: Light yellow to tan

Key Parameters:

- Melt Viscosity: 5,000–15,000 cP @ 177°C

- Set Time: <3 seconds

- Coatability: Compatible with polyolefin films and non-woven backings.

Applications: Packaging tapes, disposable hygiene products, and bookbinding.

Advantages: - 100% solids formulation eliminates VOC emissions.

- Rapid production speeds reduce energy consumption.

Unique Selling Points

- Cost Leadership:

By synthesizing raw materials in-house (e.g., styrene block copolymers and rosin esters), we bypass market price fluctuations and offer 15–25% lower pricing than competitors. - Eco-Friendly Formulations:

Our water-based and UV-curable PSAs reduce carbon footprint by 30%, aligning with global sustainability mandates. - Rapid Prototyping:

Submit your specifications, and receive custom PSA samples within 72 hours—accelerating your time-to-market. - Global Logistics Network:

Warehouses in Asia, Europe, and North America ensure timely delivery, supported by real-time order tracking.

Production Process

Our vertically integrated manufacturing ensures precision at every stage:

- Raw Material Synthesis:

- Polymerization reactors produce acrylic copolymers and SBC elastomers.

- Tackifiers derived from renewable rosin ensure consistent peel strength11.

- Formulation & Compounding:

- Proprietary blends of resins, plasticizers, and stabilizers optimize adhesion and aging resistance.

- In-line QC checks validate viscosity, tack, and cohesion.

- Coating & Curing:

- Solventless slot-die coating minimizes waste.

- UV curing tunnels enable instant cross-linking for high-performance tapes.

- Slitting & Packaging:

- Automated systems convert jumbo rolls into custom widths (10mm–1,500mm).

- Anti-static liners protect pressure sensitive adhesives integrity during transit.

Industry Applications

Automotive

- Lightweight Bonding: PSAs replace mechanical fasteners in interior trim, reducing vehicle weight by up to 20%.

- Noise Reduction: Viscoelastic films dampen vibrations in EV battery modules.

Electronics

- EMI Shielding: Conductive PSAs ground components in 5G devices.

- Flexible Circuits: Low-outgassing adhesives ensure reliability in foldable displays.

Healthcare

- Skin-Safe Adhesives: Hypoallergenic formulations for wound care and wearable sensors.

- Sterilization Resistance: Withstand autoclave cycles at 135°C.

Sustainability Commitment

- Recyclable Backings: PET and PP films designed for easy separation during recycling.

- Renewable Energy: Solar-powered facilities cut CO2 emissions by 1,200 tons annually.

Quality Assurance

Every batch undergoes rigorous testing:

- Peel/Shear/Tack: ASTM D3330, D3654, and D1002.

- Aging Resistance: 85°C/85% RH chamber for 1,000 hours.

- Biocompatibility: ISO 10993 certification for medical-grade adhesives.

Why Choose Great Adhesive?

- 25+ Years of Expertise: Trusted by Fortune 500 companies globally.

- 24/7 Technical Support: Our chemists troubleshoot your bonding challenges in real time.

- Volume Discounts: Orders above 10,000 rolls qualify for tiered pricing.

Reviews

There are no reviews yet.