The invisible guardian of the medical field

PSA for medical

Great-adhesive brand PSA for Medical is designed specifically for medical applications, combining excellent adhesion,

biocompatibility and comfort to provide reliable solutions for patients and medical staff.

PSA is a special adhesive that can quickly adhere to the skin or other material surfaces under light pressure without the need for solvents or high temperatures.

It has moderate viscosity, which can firmly fix medical devices while avoiding damage to the skin when removing them.

This property makes it an indispensable material in the medical field.

PSA Precise performance, reliable guarantee

- Adhesion: Initial adhesion (stable adhesion within 10-30 seconds) ensures that the medical device will not loosen during use.

- Temperature resistance: Maintains stable performance in the temperature range of -20℃ to 60℃, adapting to different environmental conditions.

- Biocompatibility: ISO 10993 certified to ensure long-term contact with human tissue is safe and non-irritating.

- Breathability: Highly breathable design reduces the risk of skin allergies and infection.

- Durability: Maintains excellent adhesion performance in both wet and dry environments, ensuring long-term use.

PSA for medical – Application

Comprehensive medical needs

Wound care

Transdermal drug delivery

Medical equipment fixation

Surgical Film Fixation with Adhesive

The hot melt adhesive used in this scenario has the following characteristics and uses:

- Maintaining a Sterile Environment: Hot melt adhesives are produced and applied without solvents, are non-toxic and odorless, and are environmentally friendly and safe, helping to maintain a sterile environment during surgery.

- Protecting the Skin: Hot melt adhesives have good biocompatibility and do not irritate the skin, effectively protecting the skin around the surgical area.

- Improving Surgical Efficiency: Hot melt adhesives cure quickly, with a short bonding time, making them suitable for high-speed automated production lines and thus improving surgical efficiency.

Wound Dressing with Adhesive

The hot melt adhesive used in this scenario has the following characteristics and uses:

Comfort: Compared to traditional dressings, hot melt adhesives are lighter and do not exert excessive pressure on the wound, enhancing patient comfort.

Antimicrobial Effects: Hot melt adhesives have good antimicrobial properties, preventing wound infections.

Promoting Healing: Hot melt adhesives can maintain a moist environment for the wound, promoting healing and reducing scar formation.

Ease of Use: Hot melt adhesives are typically easy to use, requiring only the application of adhesive to the wound surface, without the need for complex bandaging processes.

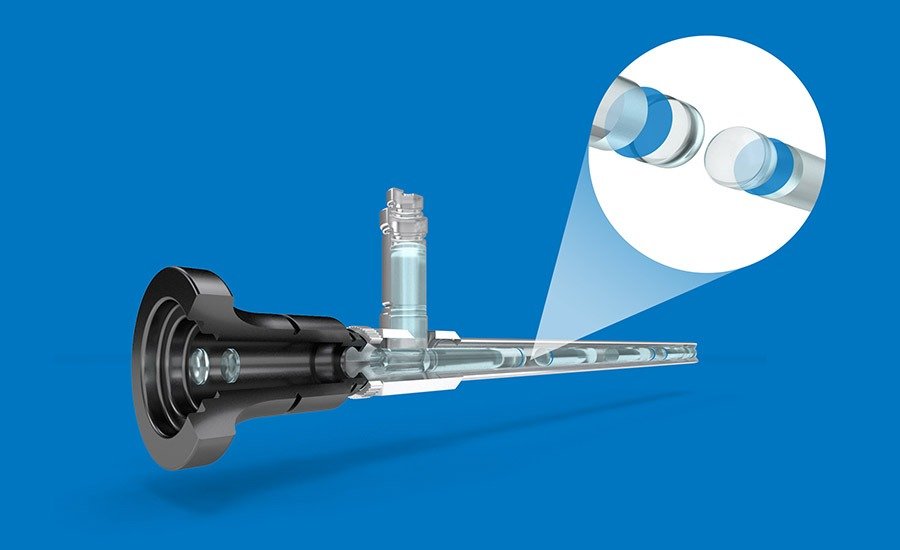

Device Assembly with Adhesive

The hot melt adhesive used in this scenario has the following characteristics and uses:

Data Recording: The system status, overall equipment effectiveness (OEE), and process data during assembly are recorded for quality tracing and improvement.

Component Fixation: Hot melt adhesives can fix components in the correct position to ensure even adhesive application.

Adhesive Dispensing: Specialized hot melt adhesive dispensers are used to apply the adhesive along predetermined paths and in predetermined amounts on the components.

FAQ

Product list

Why choose Great-Adhesive?

No matter what kind of customized service you need, we can provide you with professional solutions