Innovative applications and solutions of hot melt adhesives in the electronics field

Application Adhesive for Electronics

Professional electronic equipment adhesive

Core application scenarios of hot melt adhesive

With the trend of precision and miniaturization of electronic products,

hot melt adhesives have transformed from traditional packaging fields to key auxiliary materials in electronic manufacturing.

| Consumer Electronics | Ultra-thin bonding (adhesive layer <0.1mm) | Foldable screen phones, TWS earbuds |

| Automotive Electronics | Temperature resistance from -40℃ to 150℃ | In-car central control screens, BMS battery management systems |

| Industrial Equipment | IP67-rated sealing and protection | 5G base stations, industrial sensors |

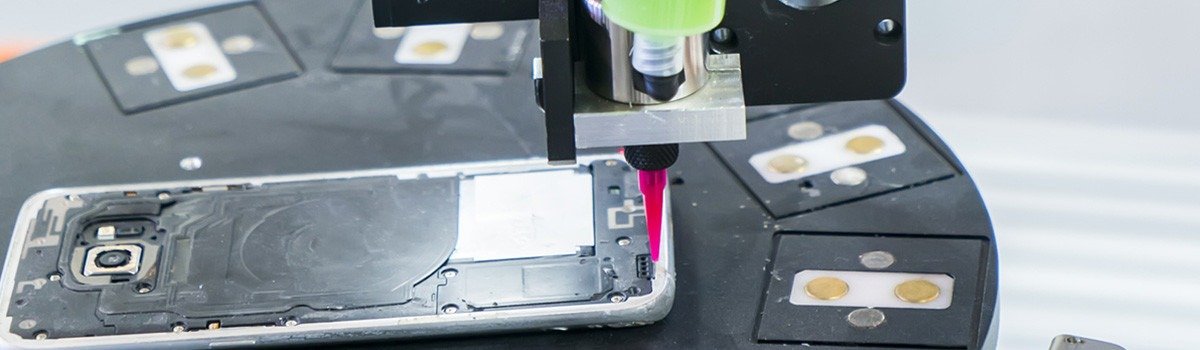

Screen fit

Our hot-melt adhesive has overcome three major technical bottlenecks in flexible screen mass production processes:

Bubble-free Control: When vacuum bonded at 0.5MPa pressure, bubble diameter <50μm

Curvature Adaptability: Withstands over 100,000 dynamic flex tests (R=3mm)

Yellowing Inhibition: ΔYI<1.5 under 3000lux UV irradiation (CIE LAB standard)

| Thickness | 100-200μm | 25-75μm |

| Curing Method | Moisture-cured | – |

| Repair Difficulty | Irreversible | Separable by heating to 80℃ |

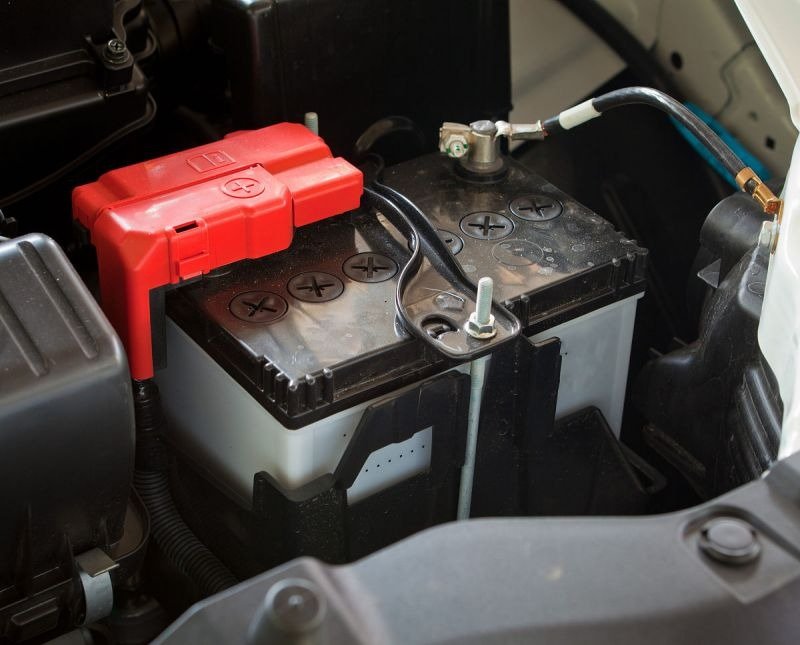

Battery Packaging

In lithium battery thermal runaway accidents, 23% are caused by packaging failures. Our hot-melt adhesive offers excellent sealing and can withstand temperatures up to 140℃.

| Type | Initial Adhesion(N/cm²) | Application Scenario |

|---|---|---|

| EVA Adhesive | 5.2 | <3%/1000h |

| PUR Adhesive | 8.7 | <1%/1000h |

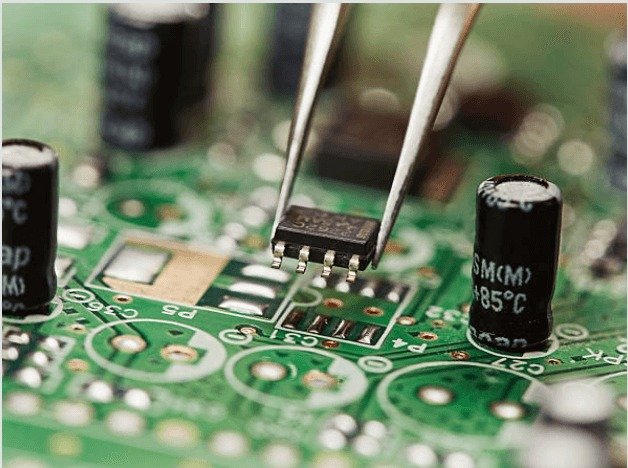

PCB component fixing

In 5G millimeter wave devices, our hot melt adhesive meets the following requirements:

High frequency adaptability: dielectric constant Dk<3.2@10GHz, loss factor Df<0.02

Miniaturization processing: dispensing line width 0.2mm, adaptable to 01005 package components

Thermal management synergy: adding 30% boron nitride filler, optimizing thermal path

Recommended Adhesive

Adhesive (Shanghai) Co.Ltd

Choosing us is not only choosing a high-performance hot melt adhesive, but also choosing a reliable and professional partner.

We are a modern factory focusing on the research and development and production of hot melt adhesives, committed to providing customers with high-quality EVA and PUR hot melt adhesive solutions. The factory covers an area of more than 6,000 square meters and has 10 advanced automated production lines, with an annual output of 9,000 tons (EVA) and 4,000 tons (PUR), respectively, to ensure the stable supply of large-scale orders.

Our EVA hot melt adhesive is widely used in board home decoration with excellent initial adhesion (>5N/cm²) and temperature resistance; while PUR hot melt adhesive has become an ideal choice for automotive interiors with its high (>25 N/cm²) super strong viscosity and excellent durability.

The factory is equipped with a professional R&D team, and more than 20 senior engineers continue to optimize the formula to ensure that the product leads the industry in key indicators such as aging resistance, curing time, and glue firmness. At the same time, strictly follow the ISO 9001 quality system, and monitor each batch of products through precision testing equipment throughout the process, from viscosity testing to temperature resistance experiments, to fully guarantee product reliability.

More than 300 professionally trained production line employees form our core strength, and our 30 sales staff help us develop our business.

Hot melt adhesive production process