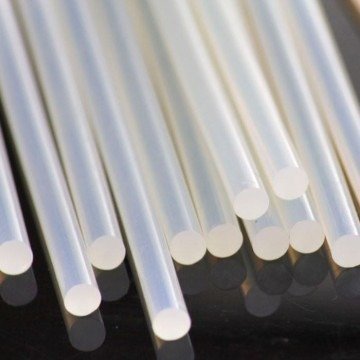

Melt glue stick

Adhesive (shanghai)co.ltd is a leading manufacturer of premium hot melt glue sticks, specializing in industrial and commercial applications. Our products are engineered to deliver unmatched adhesion, versatility, and cost efficiency, backed by vertically integrated production that ensures quality control from raw materials to finished goods. With over 20 years of expertise, we supply industrial hot glue guns and adhesive solutions to industries ranging from packaging and electronics to textiles and automotive manufacturing.

Product Parameters and Specifications

1. Material Composition

Our hot melt adhesive sticks are made from advanced thermoplastics including:

Ethylene Vinyl Acetate (EVA): For general purpose bonding, it is flexible and can bond porous materials such as cardboard, wood and fabrics.

Polyolefin (PO): Designed for challenging substrates such as polypropylene (PP) and polyethylene (PE), ensuring chemical and moisture resistance.

Copolyamide (CoPA): High-performance formulas with 60-80% bio-based content, heat resistance (>150°C), oil resistance and durability for automotive and electronic applications.

Biodegradable Options: Eco-friendly hot melt adhesive sticks with 45% bio-based content, certified for biodegradability according to ASTM D6400, and approved by the FDA for indirect food contact.

2. Temperature Performance

High-Temperature Glue Sticks: Work at 163-204°C (325-400°F), ideal for heavy-duty industrial bonding.

Low-Temperature Glue Sticks: Work at 121-149°C (250-300°F), ideal for heat-sensitive materials like foam or delicate fabrics.

3. Sizes & Compatibility

Standard Sizes: 5/16-inch (7 mm), 1/2-inch (12 mm), 5/8-inch (15 mm), 1-inch (25 mm), and 1.75-inch (43 mm) glue sticks.

Special Sizes: Compatible with 3M Polygun TC, LT, and PG II Systems for high-volume applications.

4. Color Options

White, Yellow, Clear: Makes edge banding of furniture panels invisible.

Colored Hot Melt Glue Sticks: Vibrant colors, including black, red, blue, gold, and silver, can be used for decorative or functional labels.

Black hot melt glue stick: UV resistant and opaque, ideal for automotive and architectural applications.

Glitter and metallic: provide aesthetic solutions for crafts and high-end packaging.

5. Certification and safety

FDA food grade compliant, can be used for indirect food contact.

Available in UL94 V0 flame retardant formulation for electronics.

REACH and RoHS compliant.

Company Introduction

Innovation Rooted in Self-Sufficiency

As a vertically integrated manufacturer, Adhesive (shanghai)co.ltd controls every stage of production—from polymer synthesis to final packaging. This allows us to:

- Reduce Costs: Eliminate middlemen and pass savings to clients.

- Ensure Quality: Rigorous in-house testing for viscosity, bond strength, and thermal stability.

- Customize Solutions: Tailor formulations for unique substrates or environmental conditions.

Sustainability Commitment

Our biodegradable and bio-based glue sticks align with global eco-initiatives, minimizing carbon footprints while maintaining industrial-grade performance.

Product Advantages & Selling Points

1. Unmatched Cost Efficiency

By sourcing raw materials directly and optimizing production, we offer hot glue stick prices 15–20% below market averages without compromising quality.

2. Industrial-Grade Performance

- High Shear Strength: Bonds withstand up to 500 PSI, suitable for pallet stabilization and machinery assembly.

- Fast Setting Time: 5–60 seconds for rapid production cycles.

- Temperature Resilience: Operate in environments from -40°F to 300°F (-40°C to 149°C).

3. Versatility Across Industries

- Packaging: FDA-approved sticks for food-safe carton sealing.

- Electronics: Non-corrosive, self-extinguishing adhesives for circuit boards.

- Textiles: Flexible bonds for synthetic fabrics and automotive interiors.

4. Customization Options

- Color matching for branding needs.

- Adjustable open time (5–60 seconds) for precise application.

Production Process

1. Raw Material Synthesis

- Ethylene and vinyl acetate monomers are polymerized under controlled conditions to create EVA pellets.

- Bio-based copolyamides are synthesized from dimerized fatty acids and diamines.

2. Compounding & Additive Integration

- Polymers are blended with tackifiers (e.g., terpene-phenol resins), waxes, and stabilizers.

- Fumed silica (5–8%) is added to reduce stringing and improve sag resistance.

3. Extrusion & Forming

- Molten adhesive is extruded into rods and cooled under precision temperature controls.

- Quality checks ensure diameter consistency (±0.1mm) and defect-free surfaces.

4. Packaging

- Sticks are sealed in moisture-resistant boxes with tamper-proof labels.

Why Choose [Company Name]?

- Global Reach: Serving 50+ countries with ISO-certified facilities.

- Technical Support: Dedicated experts assist with substrate testing and glue gun compatibility.

- Bulk Discounts: Volume pricing for orders exceeding 1,000 lbs.

Applications Spotlight

- Food Packaging: Biodegradable sticks seal cereal boxes and frozen food cartons.

- Electronics Manufacturing: V0-rated adhesives secure wires and insulate components.

- Automotive Assembly: Heat-resistant copolyamides bond headliners and filters.

- Woodworking: Fast-setting EVA bonds joints without clamping.

If you would like to know more about Adhesive (Shanghai) Co. Ltd or have any questions, you can contact them via:

Tel: +86 15618525178

Email: emily.gu@great-adhesive.com

Reviews

There are no reviews yet.