Adhesive for woodworking

Differences hot melt adhesive raw materials

EVA hot melt adhesive

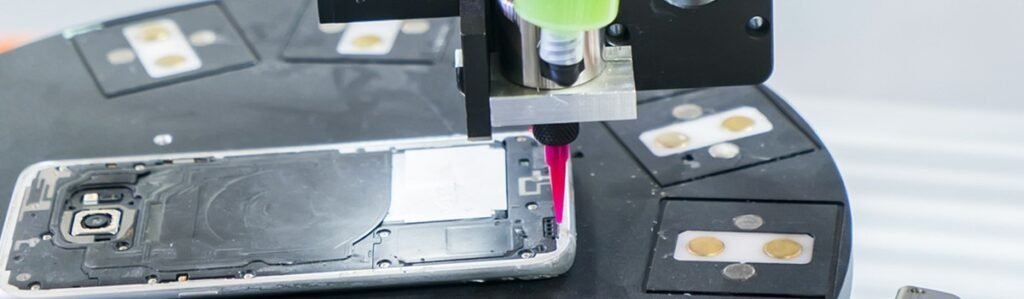

EVA hot melt adhesive is an affordable and widely used adhesive suitable for a variety of woodworking applications. It has fast bonding, high strength and good aging resistance, making it very suitable for scenarios such as furniture manufacturing, board processing and cabinet customization. For example, 25kg of Great-adhesive EVA hot melt adhesive can be used for edge banding of 3,500 meters of board, while reducing waste and downtime in the production process.

PUR hot melt adhesive

PUR hot melt adhesive stands out for its excellent bonding strength, durability and environmental protection characteristics. Compared with EVA hot melt adhesive, PUR hot melt adhesive can provide higher bonding strength and longer service life. It solidifies by chemically reacting with moisture in the air to form a cross-linked polymer structure, thereby ensuring the stability and durability of the bond. PUR hot melt adhesive is particularly suitable for high-demand woodworking applications, such as laboratory furniture, kitchens, bathrooms and other high-temperature and high-humidity scenes. Our PUR hot melt adhesive 20KG can seal the edges of 9,500 meters of boards. It can effectively resist the erosion of heat, moisture and chemicals, ensuring that the edge sealing surface remains intact for a long time.

Other scope of use