PSA For Textiles & Footwear

PSA, or pressure-sensitive adhesive, is a very practical adhesive. It can quickly adhere to materials by only applying a slight contact pressure without the need for external conditions such as heating or solvent activation. It is widely used in the production of labels, tapes, etc. Its unique adhesion properties come from the interaction between the colloidal molecules and the surface molecules of the adhered material. When PSA contacts the surface of the adherend, under the action of pressure, the colloidal molecules can closely approach the surface molecules of the material and attract each other, thus forming a strong adhesion.

How PSA works

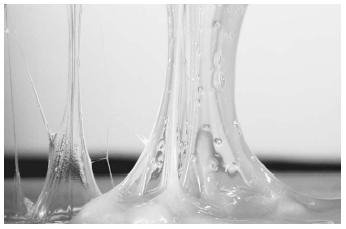

When pressure is applied to PSA, the colloid begins to flow, and this flow characteristic allows PSA to fully contact the surface of the substrate to be adhered. Intermolecular forces, including van der Waals forces, are formed between the colloid molecules and the molecules on the surface of the substrate. As time goes by, PSA gradually wets the surface of the substrate further, increasing the contact area between the colloid and the substrate, and the intermolecular forces continue to increase, thereby obtaining a more stable adhesion strength. This adhesion process does not require complex chemical reactions, but can be achieved only by physical action, making PSA easy and quick to operate during use.

PSA performance characteristics

PSA has high adhesion and tearability, which allows it to adhere to materials firmly during use and be easily torn off when needed, without leaving difficult-to-clean residues on the surface of the adhered material. Its key performance indicators are initial adhesion, sustained adhesion and cohesion. Initial adhesion refers to the adhesion ability of PSA when it first contacts the adhered material, which determines whether the adhesive can quickly adhere to the surface of the material; sustained adhesion reflects the ability of PSA to maintain adhesion for a certain period of time, which is crucial to ensure the durability of the bonding effect; cohesion is the bonding strength inside the PSA colloid, and its size affects whether the adhesive is easy to break from the inside when subjected to force.

PSA classification

Advantages Of PSA For Textiles & Footwear

Efficient and convenient production

Using PSA for bonding can improve the bonding strength between the sole and the upper. Traditional bonding methods may lead to a decline in shoe quality due to problems such as long glue curing time and weak bonding. PSA can achieve rapid bonding in a short time, and its adhesion strength is high and can withstand greater pressure and friction. This makes the shoes more durable during wear and less likely to have the soles fall off. At the same time, the good elasticity and toughness of PSA can also provide better cushioning performance for the shoes and improve wearing comfort.

Good bonding performance

PSA’s ability to form strong bonds with a wide range of materials is essential to ensure the quality and durability of textile footwear. Whether it is textile fibers, leather or various plastic materials, PSA can effectively bond them together. During dynamic wear, shoes are subject to various forces such as friction, tension, twisting, etc. The high adhesion and cohesion of PSA enable it to resist these external forces and maintain a tight bond between shoe materials, thereby extending the service life of the shoe. For example, at the bonding point between the sole and the upper of a sports shoe, PSA can withstand the repeated friction and tension generated during exercise to ensure that the sole does not fall off or debond.

Comfort and safety

From the perspective of comfort, PSA is non-toxic, harmless and non-irritating to the skin. This makes it very suitable for textile footwear parts that come into direct contact with the skin. For example, the insole is a part that comes into direct contact with the foot. Using PSA to fix the insole can avoid the irritation and allergic reactions that traditional adhesives may cause to human skin. At the same time, the flexibility and elasticity of PSA can also provide better comfort for the wearer. In terms of safety, PSA does not release harmful chemicals during use, which meets environmental and health requirements.

Application

Specific application examples of PSA for textiles and footwear